Home Channel News, Sept 1, 1999 by R. Michelle Breyer

People like the idea of what we’re doing,” said Al Hull, a sales associate with Tarboro, N.C.-based The

Joinery, which also sells products through its Natural Woods and Wood House subsidiaries. “We’re

recycling – not cutting down trees.”

Many homeowners and builders like the unique look of wood that has endured the decades.

For that reason, there has been a steady and increasing demand, not just in the United States but throughout the world, for reclaimed wood products.

“The wood has a beautiful sheen and patina,” said Ed Korceak, executive director of the National Wood

Flooring Association in St. Louis.

In addition to its unique look, the reclaimed wood typically is available in wider widths and longer lengths because it comes from large timbers.

But it’s not cheap. While new oak flooring might cost $4 a foot, a foot of reclaimed pine runs closer to $8.

Reclaimed lumber is sold primarily through specialty flooring dealers and contractors. But some home

improvement retailers, such as Home Depot’s Expo Design Centers and Lowe’s, also special order it for

customers.

“Some of our flooring programs use reclaimed wood,” said Wes Macauley, general manager of the Home

Depot Expo in Huntington Beach, Calif. “People are looking for an older rustic look — old planks with

larger knots. It’s very hard to replicate that look.”

The Home Depot Expo also features a kitchen vignette using reclaimed wood.

The reclaimed lumber business grew at around 7 percent last year, compared to 14 percent growth for the rest of the wood flooring industry, according to the flooring association But the slower growth has more to do with supply than demand Korceak said.

“The restraint is the limited supply,” he said.

The flooring association lists nearly two dozen companies specializing in reclaimed woods — from mom and pop operations to large national companies. And all of them are scouring the country for old buildings slated for demolition.

“It’s a constant battle to gel supply,” Hull said. “And each year, it gets a little more difficult. We have to work harder to get product to sell.”

For The Joinery, and most other companies, that search mostly takes them east of the Mississippi River.

Unlike today’s commercial buildings, which typically are constructed with steel, the industrial structures of a century ago were built with wood.

It takes four to six weeks to produce an order for a customer, Hull said.

In 1994, The Joinery purchased the old Sears, Roebuck and Co. Catalog Building in Chicago. Built in 1887, the former mail-order plant and office complex was the largest “stick” building ever built. It took nearly three years for the company to reclaim the building’s 12 million feet of pine timbers, which originally came from a pine forest in southeast Louisiana.

Over the years, The Joinery has gotten wood from an old Campbell’s Soup building in Camden, N.J., an H.J.

Heinz building in Pittsburgh and an old R.J. Reynolds building in Winston-Salem, N.C.

The company got wood From old American Motors building in Kenosha, Wis., that predated the automotive era. The last car built there was a Rambler. Every customer who buys wood from The Joinery receives a certificate that verifies the wood’s origin. The Joinery and other companies in the reclaimed lumber business, only take wood from buildings already slated for demolition. The demolition companies usually contact The Joinery when a building is slated to be razed. “We don’t tear down historic buildings,” Hull said.

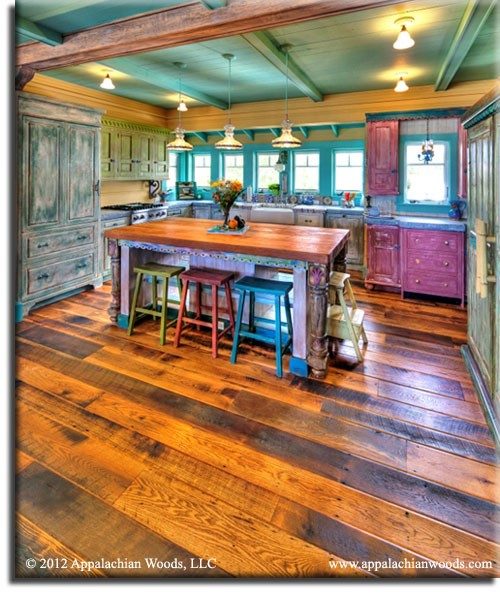

Appalachian Woods works with demolition companies around the country to get its wood, especially with a surge in demand over the past three years, said Raymond Hochstetler, marketing manager for the Stuarts Draft, Va.-based company. The company also contacts cities and counties to find out what buildings are being condemned.

“When (demolition companies) come across a building to be demolished, it’s worth their time now to be

more careful with the wood as it’s being taken down,” Hochstetler said. “Ten years ago they might have just smashed it down to the ground and carted it off to a landfill. Now they take it down piece by piece to save the wood.”

Over the years, the company has gotten wood from flour mills, coal mines and abandones houses. The last batch came from a warehouse in Chicago.

Flooring made from reclaimed oak lumber

York, Pa.-based Aged Woods recycles destined-for-the-dump am wood into wide-plank looting, paneling

and moldings. These old barns usually range in age from 75 to 200 years old.

“Our woods are distressed by Mother Nature, aged by Father Time,” according to the literature of Aged

Woods, one of the largest companies in the reclaimed woods industry.

Aged Woods was started in 1984 by Donald Sprenkle Jr., who was restoring an old stone house. He wanted to use cypress in his bathroom and shower and contacted a “used wood dealer” who found him some wood from mushroom houses in southeastern Pennsylvania. He found out about other friends who were interested in buying similar wood. He decided to create a company to sell recycled wood.

The company now sells its flooring products to wood flooring dealers and contractors in the United States, Canada, Israel, Singapore and Hong Kong. While the majority of its sales are for houses, the fastest-growing segment has been commercial applications.

Because of the limited supply, some companies are making new wood look old. Richard-Marshall Fine Flooring, which does sell some reclaimed wood, came out with its Old Boards line in 1995. It uses a 31-step process to create the look of age. Richard Hirsch, CEO of the company, said old wood can have its drawbacks, including bugs, mold and splinters.

“Because we make it in the shop, it’s consistent” Hirsch said.

The Joinery also has been working on a new wood product that will mimic old wood.

“We fear we may run out of old buildings,” Hull said.

COPYRIGHT 1999 Lebhar-Friedman, Inc.

COPYRIGHT 2000 Gale Group

Please send us an email at sales@appalachianwoods.com with details.