American chestnut reclaims its stature

Wood is sought for furniture, cabinetry and paneling

By Brian Caldwell / Staff Writer

About 100 years ago, one would be hard-pressed to find a town or city east of the Mississippi River that didn’t have chestnut trees. But that came to a screeching halt when the chestnut blight first appeared in New York City. By the 1940s the blight had affected the entire area and the tree had all but disappeared. The chestnut had only managed to escape the blight in a few pockets in the western United States, such as portions of the Sierra Nevada Mountains.

With the American chestnut (Castanea dentate) all but gone, the reclaimed lumber and flooring business has emerged as a viable source for the treasured wood, which exhibits a rustic appearance with nail holes, saw marks and knots. The source for chestnut is usually old barns or structures torn down for the wood. “The biggest demand in chestnut is for wood flooring. Second would be lumber for cabinetry, furniture building, that kind of thing,” said Raymond Hochstetler of Appalachian Woods Antique Flooring & Lumber in Stuarts Draft, Va. “Most of the lumber is original 1″ and 2″ planking, so original 4/4 and 8/4 is how we sell most of our chestnut lumber rather than taking beams and resawing them. Most widths range from 4″ to 8″; the biggest yield on rare occasion is up to 15″, 16″. In the reclaimed business, I would say chestnut is the most difficult to obtain.

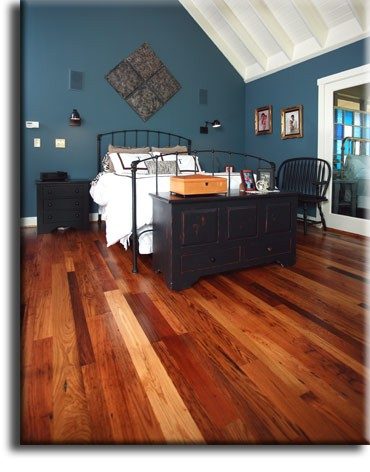

The heartwood of American chestnut is reddish-brown with light-colored sapwood that darkens with age. The grain is straight and the texture is coarse. When prevalent, the trees would reach heights up to 90′ with widths of 2′ to 4′. Chestnut splits easily, so nailing is not recommended unless holes are pre-bored. But overall, it’s considered an easy wood to work with tools and machines.

“We provide our chestnut predominantly for flooring but we do run across some old chestnut beams as well,” said Brent Kroh of Elmwood Reclaimed Timber in Kansas City, Mo.

“These beams have the original age, coloring and surface. “But overall, chestnut is getting much more difficult to obtain. It was one of the hotter woods when the reclaimed [market] started up about 30 years ago. This is my guess: I think people wanted it because it is not available anymore. You can’t obtain it from a freshly cut tree. So it is one that has been used more often than not in the reclaimed industry because it is not as available anymore.”

In its heyday, American chestnut was used for a variety of items including furniture, musical instruments caskets, boxes, crates, interior trim, fence posts, shingles, woodenware and novelties. The bark was used in the leather industry as a source of tannin. Edible nuts in small prickly burrs were a prized source of food.

The majority of chestnut flooring is sold as tongue and groove, and averages between $15 and $25/sq. ft., with higher prices for wider stock. Chestnut is also offered as cabinet lumber, which is basically a rough-sawn material, at $21 to $26/bf, depending on thickness.

Despite the high price tag, chestnut continues to have a strong appeal, according to Hochstelter.

“I believe it is the combination of the color, distressed look and the history of it. It was such a predominant wood species, very common here on the East Coast and the Appalachians. And now to be able to have some of that wood that’s no longer commercially available as a floor in your home or furniture made from it is a big appeal.

“I also think there is going to come a time when it is just not going to be very readily available. I don’t have a clue as to how long that will be. It’s still coming in fairly regularly, but I’ve noticed the trend in the last five years or so that it continues to become more difficult to find guys who have it available and the price continues to go up.”

Please let us prepare a free custom quote to best fit your project: Online Form or 800-333-7610